เครื่องสกัดน้ำมันกัญชา Cannabis SFE เครื่องสกัดด้วยตัวทำละลายคาร์บอนไดออกไซด์ที่สภาวะเหนือจุดวิกฤตยิ่งยวด

เครื่องสกัดด้วยตัวทำละลายคาร์บอนไดออกไซด์ที่สภาวะเหนือจุดวิกฤติยิ่งยวด (Supercritical carbon dioxide extraction)

Made in USA.

รหัสสินค้า : SFESFT001

| ราคา |

0.00 THB |

| จำนวนที่จะซื้อ | |

| ราคารวม | 0.00 THB |

เครื่องสกัดน้ำมันกัญชา Cannabis SFE เครื่องสกัดด้วยตัวทำละลายคาร์บอนไดออกไซด์ที่สภาวะเหนือจุดวิกฤตยิ่งยวด

รุ่น Cannabis SFE 1x1L

CannabisSFE – Supercritical CO2

Extraction Unit

Optimized for Processing of Medicinal Cannabis and Natural Herbal Products

- One Liter, Expandable CO2 Extraction System

- Base Package Vessel Capacity of 1 Liter

- Wide Pressure & Temperature Range (10,000 psi / 120°C)

- Efficient Pneumatic Liquid CO2 Pump / Waterless Pre-Chiller

- Upgrade to Cascade Mode – Can Yield up to 120grams/hour

- (Raw Material Dependent)

- Optional: CO2 Recycle, Raw Material Bags, Loading Fixture

- ASME Code Compliant Vessels and Components

The CannabisSFE has been designed to obtain high quality extracts from all parts of the cannabis plant. The system utilizes the environmentally friendly technique known as supercritical CO2 extraction. By incorporating a flexible processing platform, it may be configured to use one, two or three 1000ml processing vessels. This modular approach affords a simple and inexpensive entry into supercritical CO2 extraction of cannabis with the opportunity to increase production capacity with a second and third vessel when greater capacity is required. With three 1000ml vessels, the unit can operate in a full cascade mode and can yield up to 120grams/hour (Raw Material Dependent). Depending on Raw Material Mix, the CannabisSFE Basic Package Yields up to 45grams of product/hour and the 2 Vessel Unit up to 60 grams/hour.

The demand for pharmaceutical grade cannabis oil has increased and this trend will continue as the therapeutic value of these extracts is recognized. Research has demonstrated the value of cannabis extracts to treat a variety of ailments such as muscle spasms, glaucoma, nausea, mood and behavioral disorders, sleep disorders, and chronic pain.

A key advantages of CO2 extraction is the ability to fine-tune the solvating power to target specific compounds. This is done by varying the pressure of the CO2, temperature, solvent-to-feed ratio, and flow rate. There is more to medical marijuana than just the two principal cannabinoids (THC and CBD) that are found in the plant. In fact, multiple biologically active compounds have been identified. However, exactly how many of these compounds and in what combinations contributes to its overall medicinal efficacy (the entourage effect) is not well understood.

สินค้าไม่เพียงพอ

สินค้าหมด

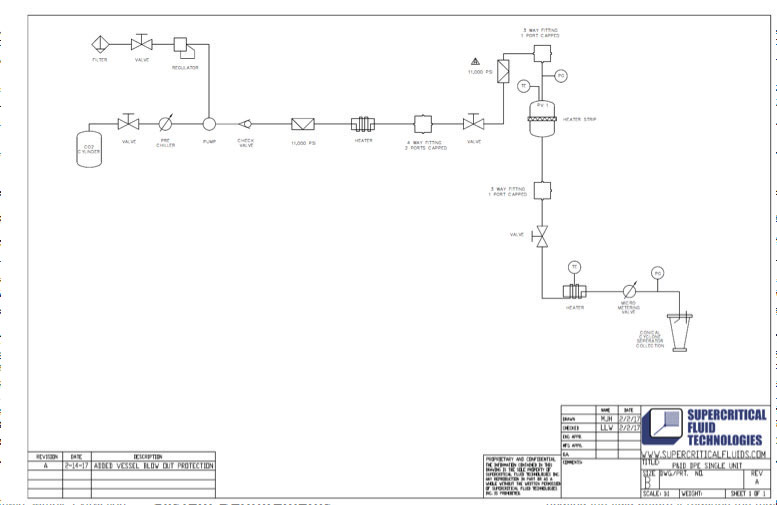

CannabisSFE P&ID 1x 1000ml Processing System

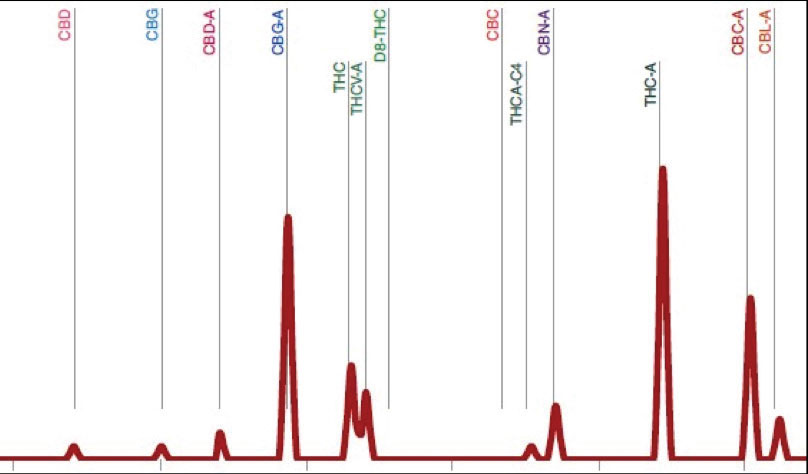

Figure 1: Smart CannaLC Analysis of Extracted Cannabis Oils Using the

CannabisSFE Processing System

System Specifications

| Standard Configuration | |

|---|---|

| Maximum Operating Pressure: | 10,000 psi (68.9 MPa). |

| Pressure Display: | Pressure gauge for each processing vessel |

| Temperature Range: | Ambient to 120˚C. |

| Temperature Precision: | +/- 0.5˚C. |

| Temperature Display: | PID Control/ LED. Displays internal vessel temperature. |

| CO2 Flow Rates: | up to 200mls/min (~176 g/min) liquid CO2 |

| Restrictor Valve: | Heated up to 120˚C; Resistant to blockage up to 200mls/min. (~176grams/min.) |

| Integrated Waterless Chiller Assembly: | The integrated Peltier waterless chiller uses thermoelectric cooling of the iquid CO2 from the delivery tank. The chilled CO2 is then delivered directly to the pneumatic supercritical fluid pump. Proper cooling of the CO2 before it arrives at the pump ensures that the CO2 is pumped in an efficient manner that eliminates pump cavitation to achieve the pressures and flow rates required for supercritical fluid extraction processes. |

| Sample Extraction Vessel: | CannabisSFE accommodates up to three, 1000ml processing vessels |

| Collection Vessel: | Externally mounted cone shaped cyclonic separator for ease in extract removal |

| Pre-heater: | Improves temperature consistency of the fluid by heating the fluid before it reaches the main sample extraction vessel(s). |

| Over-Pressure Safeguards: | Rupture disc assembly. |

| Instrument Control: | Vessel and preheater temperature controlled by PID-Fuzzy Logic Controllers. Pressure controlled by manual regulator. |

| Dimensions: | CannabisSFE basic package 1x 1000ml: Width: 27.00”, Depth: 14.36”, Height: 30.13” |

| Weight: | CannabisSFE basic package: 140 lbs. |

| Available Options | |

| Additional 1000ml Processing Vessel Assemblies | |

| Allowing up to Full Cascade Operation: | Easily field installed upgrades to processing capacity that allow added processing capabilities as needs evolve. |

| Sample Loading Fixture: | Allows ease in loading raw materials into polyester 150 micron/100 mesh sample bags (or other sample bag materials) and into the 1000ml vessel of the CannabisSFE Unit. |

| Raw Material Sample Bags: | 1000ml polyester 150 micron/100 mesh sample bags. Allows ease in loading raw materials into and removing from the processing vessels. |

| Robot Couple Blixer3™: | Grinding plant material will increase the surface area and load of material into the extractor which increases extraction efficiency. This grinder performs particle reduction fast and efficiently and will grind 300-400 grams of dried trim/flower down to approximately 200 microns in 3-4 seconds. |

| System Requirements | |

| Power Requirements: | 220 VAC, 50/60 Hz. |

| Liquid Gas Supply: | Liquid CO2 cylinder with dip tube. |

| House Air: | Dry air, regulated to 110 psi (760KPa) and 15 SCFM. |